Non-catalytic Stoves

Non-catalytic StovesNon-catalytic stoves do not use a catalyst, but have three internal characteristics that create a good environment for complete combustion. These are firebox insulation, a large baffle to produce a longer, hotter gas flow path, and pre-heated combustion air introduced through small holes above the fuel in the firebox.

Non-cats cannot match the even heat output of catalytic stoves, but their owners love watching the beautiful fire they create. The baffle and some other internal parts of a non-catalytic stove will need replacement from time to time as they deteriorate with the high heat of efficient combustion.

Although most of the stoves on the market are non-cats, some of the most popular high-end stoves use catalytic combustion. Because they are slightly more complicated to operate, and the best of them do produce exceptional performance, catalytic stoves are suited to people who like technology and are prepared to maintain the stove properly so it continues to operate at peak performance. Both options have their pros and cons.

Catalytic Stoves

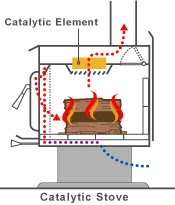

Catalytic StovesIn catalytic combustion the smoky exhaust is passed through a coated ceramic honeycomb inside the stove where the smoke gases and particles ignite and burn. Catalytic stoves are capable of producing a long, even heat output.

All catalytic stoves have a lever-operated catalyst bypass damper, which is opened for starting and reloading. The catalytic honeycomb degrades over time and must be replaced, but its durability is largely in the hands of the stove user. The catalyst can last more than six seasons if the stove is used properly; but if the stove is over-fired, garbage is burned and regular cleaning and maintenance are not done, the catalyst may break down in as little as 2 years. (EPA note: Garbage should never be burned in a wood stove or fireplace.)

No comments:

Post a Comment